Awesome welding man.

I'm in the middle of welding a cart for the new tig and some stairs for the garage attic.

Regards,

Rob

Great Basin Welding

Blue welders

Red welders

My luscious Table

DIY TIG Torch cooler

My last weld before layoffs...some 6'' 160 wall knocked out 3 of em before the day was out! Was so tired

~1987 Lincoln Sa-200~

~1978 Miller Big 40~ (restored)

~and everything inbetween~

lyc 0-540 crop duster exhaust going south of the border

'14 HTP invertig 221

Thermal Arc 201ts

'15 HTP 2400

'13 Hypertherm Powermax 30

Esab 875

Esab 251

Clark Metal Service

specializing in stainless steel exhaust systems

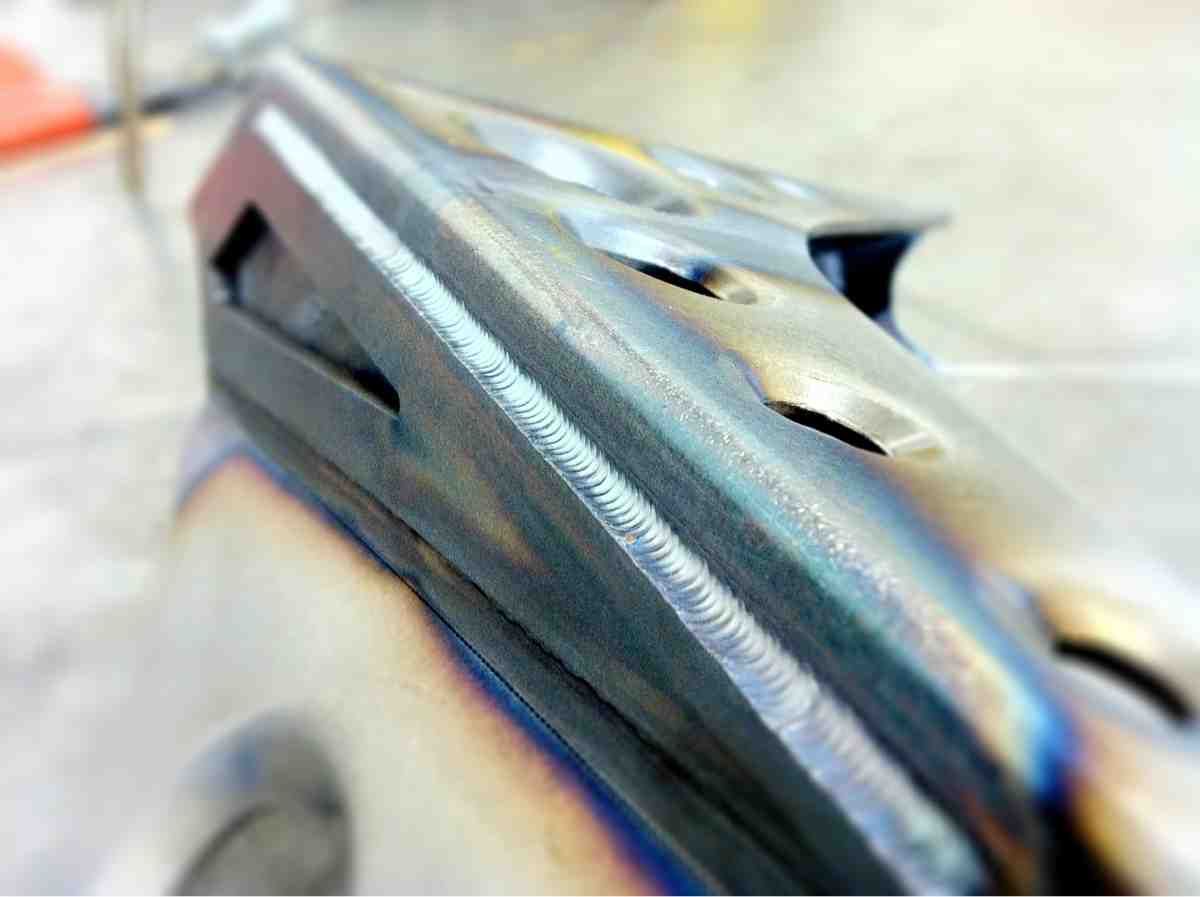

Gorgeous!

Regards,

Rob

Great Basin Welding

Blue welders

Red welders

My luscious Table

DIY TIG Torch cooler

Welded up some shock mounts I made for an offroad car.

All 1/8" 4130

are you able to do that all continuos? looks great, if you're starting and stopping you are doing an excellent job masking it (not to mention just phenomenal welds period).

'14 HTP invertig 221

Thermal Arc 201ts

'15 HTP 2400

'13 Hypertherm Powermax 30

Esab 875

Esab 251

Clark Metal Service

specializing in stainless steel exhaust systems

tad different kind of welding today

Used my new 3D printer to make this object! The plastic comes on a spool similar to Mig wire, like a cnc machine just goes round and round and up one layer at a time to print! Thought itd interest some of you guys! Tomorrow I start welding my SS but I am going to be looking up TIG welding. My father bought a Llincoln 225 a few years ago and has used it less than an hour, so I want to learn after seeing everyones TIG welding on here

Okay, here on the forums, I think the administrators should create an entirely new category called "What is ZTFab up to?" Paul, you're just in a class of your own.

Lincoln Power Mig 216

Lincoln AC/DC-225/125

Miller 625 X-Treme Plasma

Miller 211

Victor Journeyman O/P

Milwaukee

Dayton

Makita

Baileigh

NRA Life Member

Beautiful work! But you will get drop out with that G-O5/Ford Gold. If you don't want to run a filter DD Power Cool, Peak Final Charge or Peak Global Lifetime(parent bore engine) would be great choices IMO. I'm not sure if the 6.0 can use Cat Elc coolants which are nitrited versions of Dexcool/Ford Orange.

Idealarc 250

AC 225S

Victor OA-older made in USA stuff.

And a crap ton of other stuff.

Did a can tonight. I get great looking beads here and there and I pull out the camera and all of a sudden the camera will make it look like ****. It's like beer goggles. So I just put my camera back in my pocket and carry on.

Did this one the other night

Tried my hand at polishing without sanding. Go figure it came out the best. Just took it to the buffing wheel. 10 seconds later it came out like this

This one came out ok as I was getting used to the welder. Bead blasted and polished and it came out like crap and then enhanced how uneven the welds were. Boooooo

Torchmate 2x2 CNC with Flashcut CNC controls

Hypertherm Powermax45

Esab ET220i

Razorweld 195 Mig

Razorweld 200ac/dc Tig

Tormach 770, Tormach xstech

Carbide3d Nomad3

Sherline 4400 CNC Lathe

They look good! You must have the same 10 year old canon camera as me! Can't justify replacing it, cause the effin thing won't die!

'14 HTP invertig 221

Thermal Arc 201ts

'15 HTP 2400

'13 Hypertherm Powermax 30

Esab 875

Esab 251

Clark Metal Service

specializing in stainless steel exhaust systems

A trick that I use for cans or any aluminum that is to look nice when done is lay a towel down on the welding table while working on the part so you don't scratch up the aluminum.

This intake as you can see has nothing done to it to clean it up, just cut and welded and care taken not to scratch it up while working on it. You could go strait to polish after welding if you take care of it while working on it.

Had to make some more pedals for a Jimco Class 10 car.

Modified the existing brake pedal (shortened it) and built a whole new clutch pedal for the Jamar master cylinders.

All 1/8" 4130.

Just wondering if you ever played the drums in a band before?

With rhythm like that you should be a drummer.

Lincoln Electric:

Ranger GXT 250

SA-200

LN-25

Pro MiG 256

Pro Mig 180

Esab CV 251

Invertec 160

Victor Torches”