-

-

-

Re: Random Projects

Also took a pic today of something I did last summer. I use a Club in my truck, the type that locks under the brake/clutch arm. The stupid handle on the chrome shaft was always coming loose and would rotate around. So I grinded off as much chrome in the weld area as possible and laid a bead of 308L around it. Problem solved:

Miller Dynasty 200 DX

BuildPro TMA52238 (38" x 22")

-

-

Re: Random Projects

Where in the heck did ya get all those dimes? Really nice work man...

(Retired) Professional firefighter, amateur everything else I try to do...

Oh yeah:

Go Big Red! (You know: one of the 12 members of the Big 10 cuz we left the 10 members of the Big 12...)

-

Post Thanks / Like - 1 Likes, 0 Dislikes

dhem

dhem liked this post

-

Re: Random Projects

Thank you.

Miller Dynasty 200 DX

BuildPro TMA52238 (38" x 22")

-

Re: Random Projects

Excellent Craftmenship. Your work looks great! Where do I sign up for a job like this? lol

Some Blue , Some Red & Some Grey

Proverbs 16:2-3.

2 "All a personís ways seem pure to them, but motives are weighed by the Lord. 3 Commit to the Lord whatever you do, and he will establish your plans."

-

Post Thanks / Like - 1 Likes, 0 Dislikes

dhem

dhem liked this post

-

Re: Random Projects

When it comes to TIG Welding, You are the best I ever seen. (Im looking at your pictures and smiling) Really! Really! Nice Work.

Some Blue , Some Red & Some Grey

Proverbs 16:2-3.

2 "All a personís ways seem pure to them, but motives are weighed by the Lord. 3 Commit to the Lord whatever you do, and he will establish your plans."

-

Post Thanks / Like - 1 Likes, 0 Dislikes

dhem

dhem liked this post

-

Re: Random Projects

Perfect practice makes perfect it seems!

-

Post Thanks / Like - 1 Likes, 0 Dislikes

dhem

dhem liked this post

-

-

Re: Random Projects

You are very good at what you are doing

A better bluing is

Force Formula 44-40 Bluing

I used that when i did touch up work on repairs / modification

Backed my

CATMA over your

CARMA oops clusmy me

What would

SATAN do

??

Miller Trailblazer 302 AirPak

Miller Digital Elite

Optrel Welding Hat

Arcair K4000

Suitcase 12RC / 12 VS

Hypertherm PM-45

Rage 3 saw

Rusty old Truck

-

Post Thanks / Like - 1 Likes, 0 Dislikes

dhem

dhem liked this post

-

Re: Random Projects

His Welds Are Better Than Sex!!

Some Blue , Some Red & Some Grey

Proverbs 16:2-3.

2 "All a personís ways seem pure to them, but motives are weighed by the Lord. 3 Commit to the Lord whatever you do, and he will establish your plans."

-

Post Thanks / Like - 1 Likes, 0 Dislikes

dhem

dhem liked this post

-

Re: Random Projects

Thanks for the heads up. Force Formula 44-40 Bluing looks like a high quality product, but the price for the larger bottle size I'd need is a bit much for my budget right now. Do you have any experience with their Oxpho Blue line?

Miller Dynasty 200 DX

BuildPro TMA52238 (38" x 22")

-

Re: Random Projects

I have heard of it but never tried it myself

A friend of mine another gunsmith gave me some of the force 44-40 he had left and i used it ever since

I had tried the casey's and was not happy with the results

Backed my

CATMA over your

CARMA oops clusmy me

What would

SATAN do

??

Miller Trailblazer 302 AirPak

Miller Digital Elite

Optrel Welding Hat

Arcair K4000

Suitcase 12RC / 12 VS

Hypertherm PM-45

Rage 3 saw

Rusty old Truck

-

Post Thanks / Like - 1 Likes, 0 Dislikes

dhem

dhem liked this post

-

Re: Random Projects

I did some reading and it looks like the Oxpho Blue creme works rather well. Also the price is excellent so I just ordered a 16oz of it as well as a gallon of the Rust Release from www.brownells.com

Miller Dynasty 200 DX

BuildPro TMA52238 (38" x 22")

-

-

Re: Random Projects

I can tell you if you talked to the people at brownells

They wont steer you wrong i have dealt with them for years

I talked to a friend of mine and he says it's great stuff he uses it also

Backed my

CATMA over your

CARMA oops clusmy me

What would

SATAN do

??

Miller Trailblazer 302 AirPak

Miller Digital Elite

Optrel Welding Hat

Arcair K4000

Suitcase 12RC / 12 VS

Hypertherm PM-45

Rage 3 saw

Rusty old Truck

-

Post Thanks / Like - 1 Likes, 0 Dislikes

dhem

dhem liked this post

-

-

Re: Random Projects

The stand is beautiful.

Makes me wanna go out in the shop and find something to blue

-

Post Thanks / Like - 1 Likes, 0 Dislikes

dhem

dhem liked this post

-

-

Post Thanks / Like - 1 Likes, 0 Dislikes

dhem

dhem liked this post

-

Re: Random Projects

For a large bluing project a gunsmith would usually do a hot tank blue which would give a more consistent color for rifles and shotguns but that takes room for the tanks and heaters and degreasing tanks ect

Only some guys who do a large amount of bluing have all that and if i wanted to do more than a small area i would just send it to one of them they do very nice work and i mainly did pistol work porting and polishing and sites and some people would want a total reblue but a lot opt for some of the newer coatings

And the fact that steel for a barrel and action are probably a more consistent steel than tubing would be

Backed my

CATMA over your

CARMA oops clusmy me

What would

SATAN do

??

Miller Trailblazer 302 AirPak

Miller Digital Elite

Optrel Welding Hat

Arcair K4000

Suitcase 12RC / 12 VS

Hypertherm PM-45

Rage 3 saw

Rusty old Truck

-

Post Thanks / Like - 1 Likes, 0 Dislikes

dhem

dhem liked this post

-

Re: Random Projects

Your my hero.

I'm new to bluing and not sure about it.

From what I'm reading its basically a ton of work to make steel look cool.

Does bluing keep the your steel from rusting? If not then do you lacquer it?

ThermalArc 161STL TIG/Stick (160amp)

Lincoln weld-pak 100 (fluxcore)

4X6 Enco bandsaw

10" skillsaw with metal blade for 45degrees (works)

4" grinder

Weld for fun. Very rare I do it for Money.

-

Post Thanks / Like - 1 Likes, 0 Dislikes

dhem

dhem liked this post

-

Re: Random Projects

Originally Posted by

FunnyDream

Your my hero.

I'm new to bluing and not sure about it.

From what I'm reading its basically a ton of work to make steel look cool.

Does bluing keep the your steel from rusting? If not then do you lacquer it?

Bluing will rust you have to keep it oiled

There is Browning / Blackening and Bluing

Backed my

CATMA over your

CARMA oops clusmy me

What would

SATAN do

??

Miller Trailblazer 302 AirPak

Miller Digital Elite

Optrel Welding Hat

Arcair K4000

Suitcase 12RC / 12 VS

Hypertherm PM-45

Rage 3 saw

Rusty old Truck

-

Post Thanks / Like - 1 Likes, 0 Dislikes

dhem

dhem liked this post

-

Re: Random Projects

Nice work, are you just using ERCuSi-A bronze filler?

-

Post Thanks / Like - 1 Likes, 0 Dislikes

dhem

dhem liked this post

-

Re: Random Projects

Thanks guys. Beyond functionality, making things look cool/nice is definitely a labor of love. At some point in time I'd like to start making money working with metal, but for now I'm just a hobbyist so I don't mind the extra work it takes. I've always liked for my stuff to deviate from the norm a bit.

As for coating it right now the stand is rubbed down with some gun oil. I do want to find something a bit more durable than just oil though. As an experiment I might have to braze up some testers, blue them and finish them with various clear coatings to see how they hold up.

The filler rod I'm currently using is Blue Demon Silicon Bronze. I've been thinking about ordering something different to try to see if I can get cleaner beads.

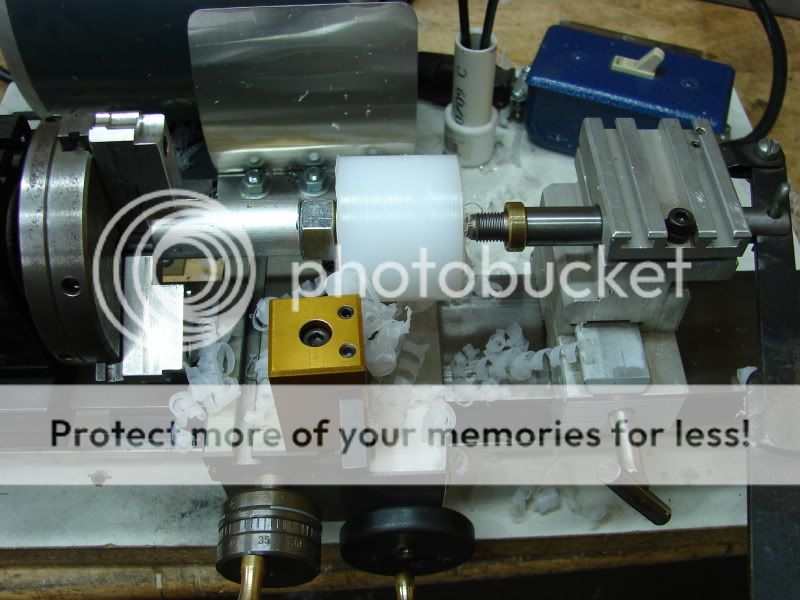

Got some more pics from the other day that I need to upload. I polished all the brazes, oiled everything, and finally machined up some feet from UHMWPE bar stock.

Last edited by dhem; 08-08-2011 at 05:54 PM.

Miller Dynasty 200 DX

BuildPro TMA52238 (38" x 22")

-

Reply

Reply