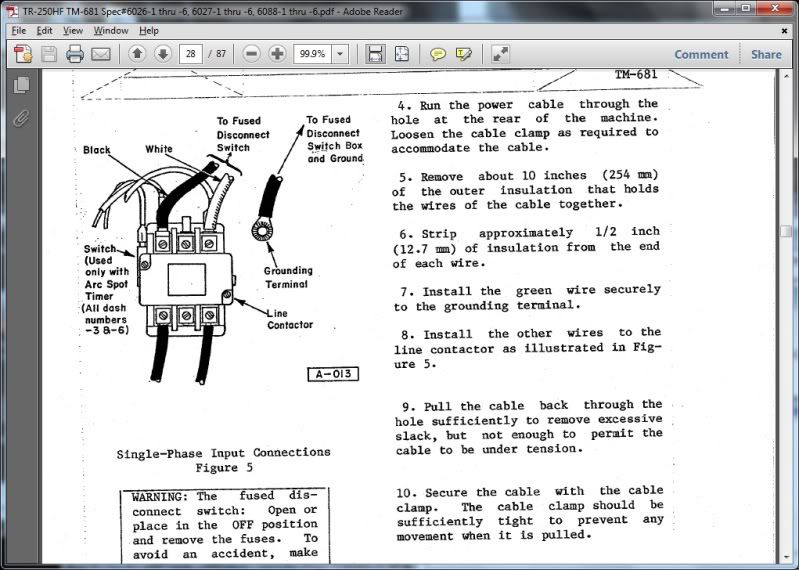

You would use the 230 volt setting. Can you provide a link to the manual? You should have something labeled L1 and L2. Those will be your two legs of 220. The third wire would be ground. Look for a ground stud attached to the chassis with the standard symbol for ground stamped or labeled nearby.

If you are uncomfortable with doing this type of wiring, let someone else do it. An error could be fatal to you and your welder.

Papa

Reply

Reply