Dry Fit.

Adam H by Zanconato Custom Cycles, on Flickr

Fluxed.

Adam H by Zanconato Custom Cycles, on Flickr

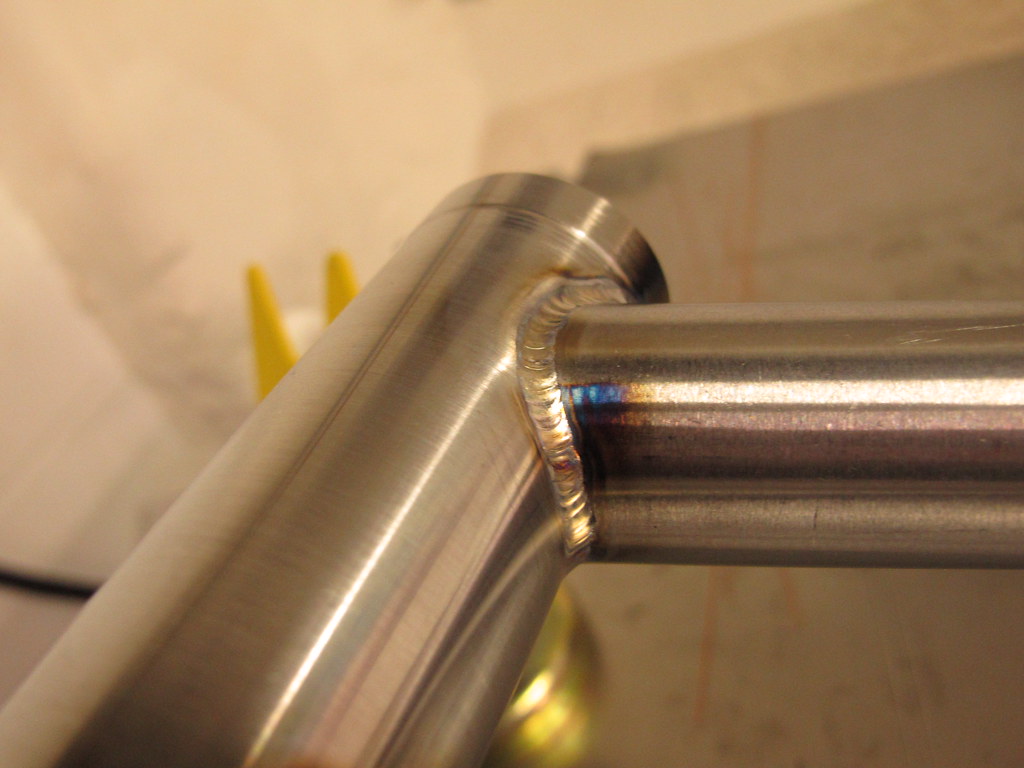

Tacked.

Adam H by Zanconato Custom Cycles, on Flickr

Brazed.

Adam H by Zanconato Custom Cycles, on Flickr

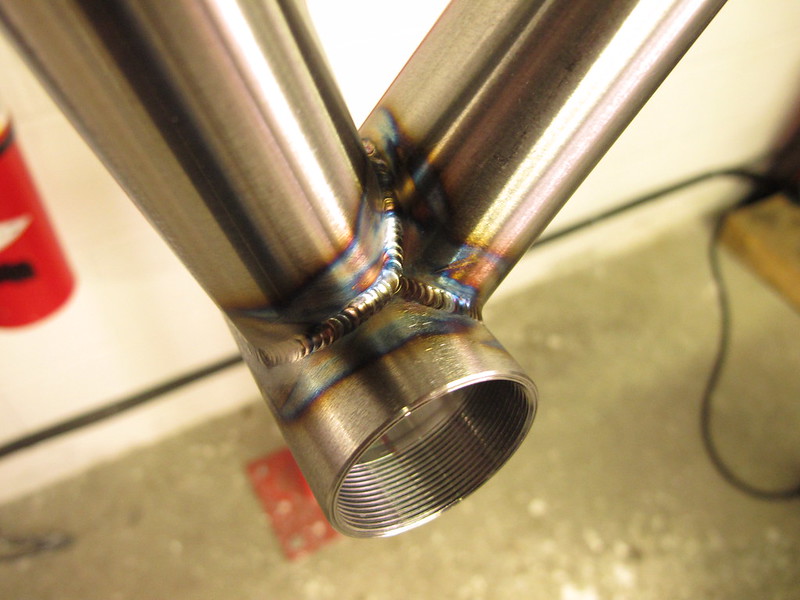

Soaked followed by a little elbow grease, emery cloth, and scotchbrite.

Adam H by Zanconato Custom Cycles, on Flickr

Reply

Reply

). I've never hosted a class before, but it would be an interesting idea. Is it something you would want to do over the winter?

). I've never hosted a class before, but it would be an interesting idea. Is it something you would want to do over the winter?