i have never tried to tig weld i was wanting to know if it is at all harder than stick, i need to know cause works gettin scarace and i may have to go singel hand and they say combo pays better

This thread is about making MIG look TIG, or really nice looking mig welds.

I am going to try something.

ONLY POST IF YOU HAVE A PICTURE OF YOUR OWN WORK.

The point is we want to SEE your attempt.

I am going to try to master this too.

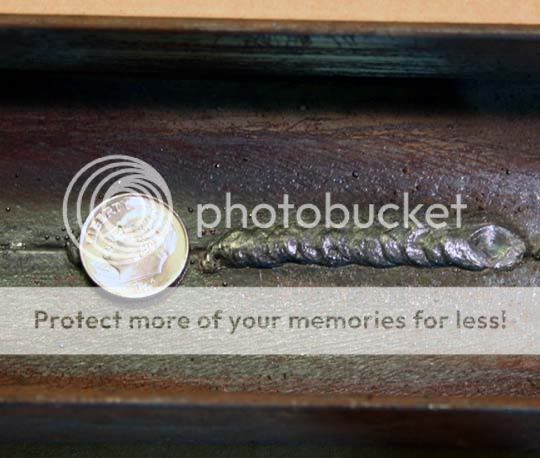

Here is my picture. It aint like ZTfabs, but it was about 200 feet of weld.

WFS 330 of .035, about 20 volts C/25. This is 3/16" square tubing so there is a natural perfect fit up. I should have been at around 200 amps.

Horizontal, making circles going up on the forward stroke. First pass on clean bare steal, second pass down through the puddle. I turn the heat WAY UP to do this. 200 amps on 3/16" horizontal groove.

Here is a link to another thread

http://weldingweb.com/vbb/showthread.php...hlight=mig+tig

Nothing discussed here but Mig welds.

David

edit: Mig gun was held straight in the joint.

Last edited by David R; 05-26-2009 at 05:56 PM.

Real world weldin.

When I grow up I want to be a tig weldor.

i have never tried to tig weld i was wanting to know if it is at all harder than stick, i need to know cause works gettin scarace and i may have to go singel hand and they say combo pays better

harder shmarder, its different. its like oa welding, heat in one hand to make the puddle, and filler in the other to feed it. in ways its easier than stick , cause thers no slag to block yer view, you see the molten metal and its up to you to make sure it goes where it should.

I was welding bucket teeth on using a forward whip and bare wire.

Mig welds that look like tig welds or attempts at it.

David

Real world weldin.

When I grow up I want to be a tig weldor.

Just curious, is this a new fashion thing or is their some good technical reason to make MIG look like TIG??

Take a look here and see what started this.

http://weldingweb.com/vbb/showthread.php?t=30507

Along with other threads about the same thing.

This is a trial thread.

David

Real world weldin.

When I grow up I want to be a tig weldor.

Here is an image that I got out of my welders manual. It shows that dragging is a real method which was challenged in another thread.

Also a meager attempt of getting the tig weld look on some crappy rusty steel. There is a photo of the welds and a photo of the inside of the box.

I did not have good steel to try it on but will try to get something better soon.

Bob

I'm glad you started this thread David. I've been wanting to try doing this and just needed a reason.

Lincoln 100 HD with .030" NR-211-MP on some 1 1/4" X 1/8" angle iron. I didn't hold it at the end quite long enough but it ain't too bad after about 5 minutes of playing around. The dime is partially covering a tack, I ran a few beads on the other side before trying this one.

I may re-post this one so you guys can critique it without hijacking this thread.

Here was my attempt on 3/8 plate to 5/8 roundbar. I used a lincoln weld pak and .035 lincoln innershield nr211mp wire. This was a table mount for my sander.

Shane

Ya gotta spend money to make money!

For my business - custom off road fabrication- it is the customers perception that these types of welds are better. Of course, appearance doesn't really have much to do with the quality. As welders we know that, but for me, aesthetically appealing welds help sales.

Here is a pic of a Dana 60 axle housing I mig welded to the tubes.

Here's a couple of my attempts at it.

These were some prototype brackets, .125" CRS.

This is a truss that I made for a 9" differential housing: I cut the truss from 2"x3"x.125" tubing.

And here is the "box" from the previous thread. It is actually a cover for an old rooftop hatch that was de-commissioned. .125" CRS.

Here's a few more...

.125" and .188" CRS.

These are both open corner joints like the "box". THere is a small piece with a lap joint on the .188" as well.

My first attempts were more like "MIG like MIG".

I cut 8 coupons of 1/8" CRS and tacked them to give myself open groove joints.

This was also my first try at pulling the torch, I usually push.

Each coupon was welded in 2 steps, from the corner to the center tack, left to right, with changes in WFS and voltage made on each half. You can see the reference marks: 1A/1B,

2A/2B, etc.

Basic settings:

Lincoln PM300 in GMAW (#5) mode....no pulse.

.035" ER70-6

92/8 Ar/Co2

Coupons tacked but needing cleaned. The "Spot" feature is cool! .5sec duration.

Coupon 1: A side, 150 WFS / 20 volts Too Hot!!....B side, 150 WFS / 17.5 volts.

Coupon 2: A side, 140 WFS / 17.5 volts....B side, 140 WFS / 16 volts....still hot.

Coupon 3: A side, 130 WFS / 16 volts....B side, 130 WFS / 15 volts....unstable arc @ 15volts, 16 seems mo' better.

Coupon 4: A side, 120 WFS / 16 volts....B side, 110 WFS / 16 volts.

Coupon 4A seems to be the best of the lot, from a WFS/Volts standpoint. I think my technique of making the "e" is too slow. Like, I'm not taking the horizontal move far enough to the right before I curve back around counter clockwise.

I spent about 1/2 an hour doing "dry runs" with the machine turned off so as to get a feel for the drag/"e" technique. The 400 amp gun is definitely NOT the one for this!

Comments and pointers will be appreciated!

Rex

No fair! I think Paul should be excluded from this "attempt"

Michael Jordan: "Just put this ball through that loop? Sure, I'll try it"

Amps or heat is the wire speed.

Volts are the bead width. You can see that in your cupons.

I would try 120 to 130 ipm with about 17 -18 volts. To your own taste of course.....

If you look at cupon 3, A side you are close, but there is too much weld or wire.

you could also try straight in and push.

I like the attempts, looks like you are on your way!

More please

David

Last edited by David R; 05-27-2009 at 07:20 PM.

Real world weldin.

When I grow up I want to be a tig weldor.

Here are a few sample T joints that I ran quite a while ago.

It is a small part, but that is all I have in here right now. I honestly can't remember if I pushed or pulled this one. I push/pull based on which side I am coming from and what I can do to get comfortable. I can also weld with either hand so right to left or left to right doesn't bother me.

For a comparison, here is a small tig weld I did recently.

Jamie Webb

Welder & Inspector

Business and Hobby

Lincoln Pro-Mig 180 with Spool Gun and Lincoln AC225

I hate guys that weld like thatIt's beautiful work, you make us all proud...I know you've listed it before, but ZT could you give your parameters again? I've got an itch to give it a go too. Hat's off to all those that showed up on this!

Thanks

maniak

That axle truss is art.

Just realised, referencing another thread, GOOD ART. didn't want any mistakes here.

past work toys; lathes,mills, drills, saws, robots, lasers ironworker, shears, brake, press, grinders, tensile tester, torches, tigs, migs, sticks, platten table, positioner, plasmas , gleeble and spot. Retired June 30, 2009.

Thanks.

I like this one that I did a little better. It's in two separate threads.

http://weldingweb.com/vbb/showthread.php?t=10922

http://weldingweb.com/vbb/showthread.php?t=11016

I wouldn't want my mig welds to look like tig. Clean and consistant, yes! But not like tig, it ain't natural. The best from my days leading up to certifying.

Lincoln V350 Pro @ 18.~plus volts and LN-7 wire feeder @ 225-ish? ipm.

Here are some tig beads from cyberspace...yeah, I can do that!

City of L.A. Structural; Manual & Semi-Automatic;"Surely there is a mine for silver, and a place where gold is refined. Iron is taken from the earth, and copper is smelted from ore."

Job 28:1,2

Lincoln, Miller, Victor & ISV Bible

Danny