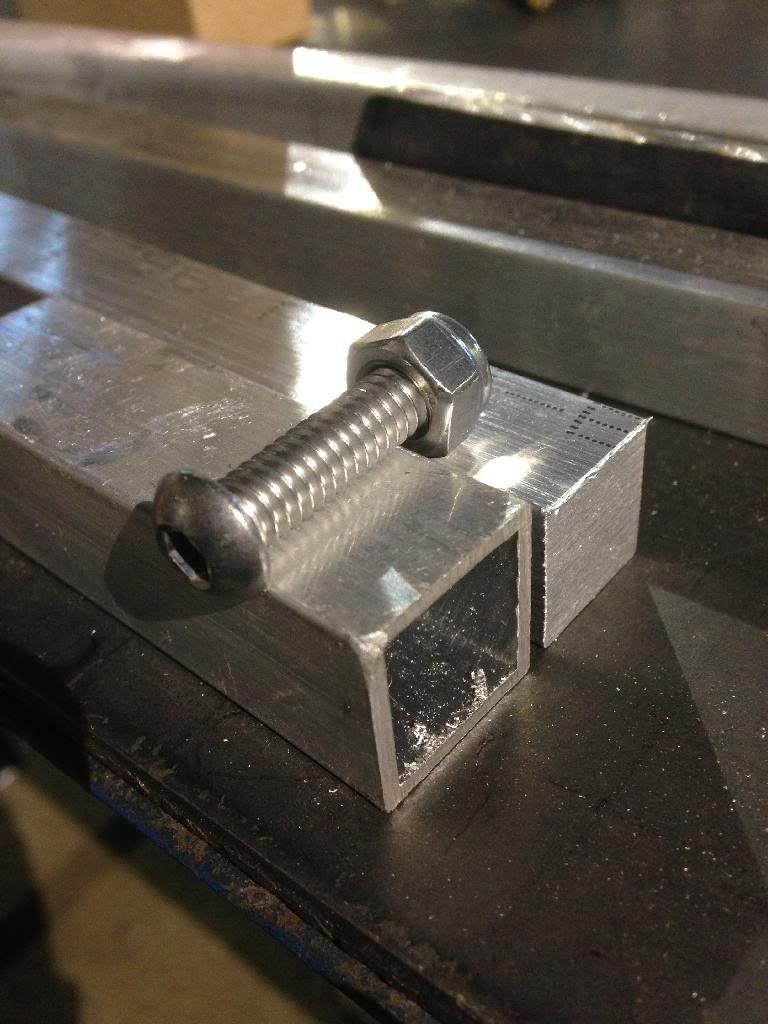

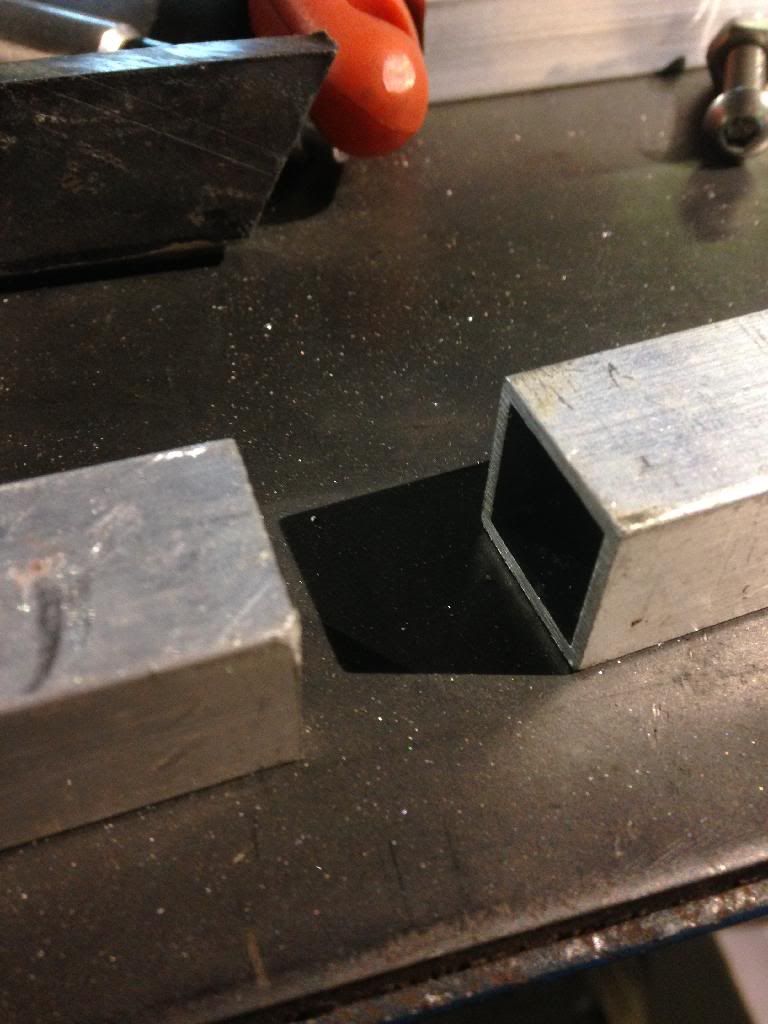

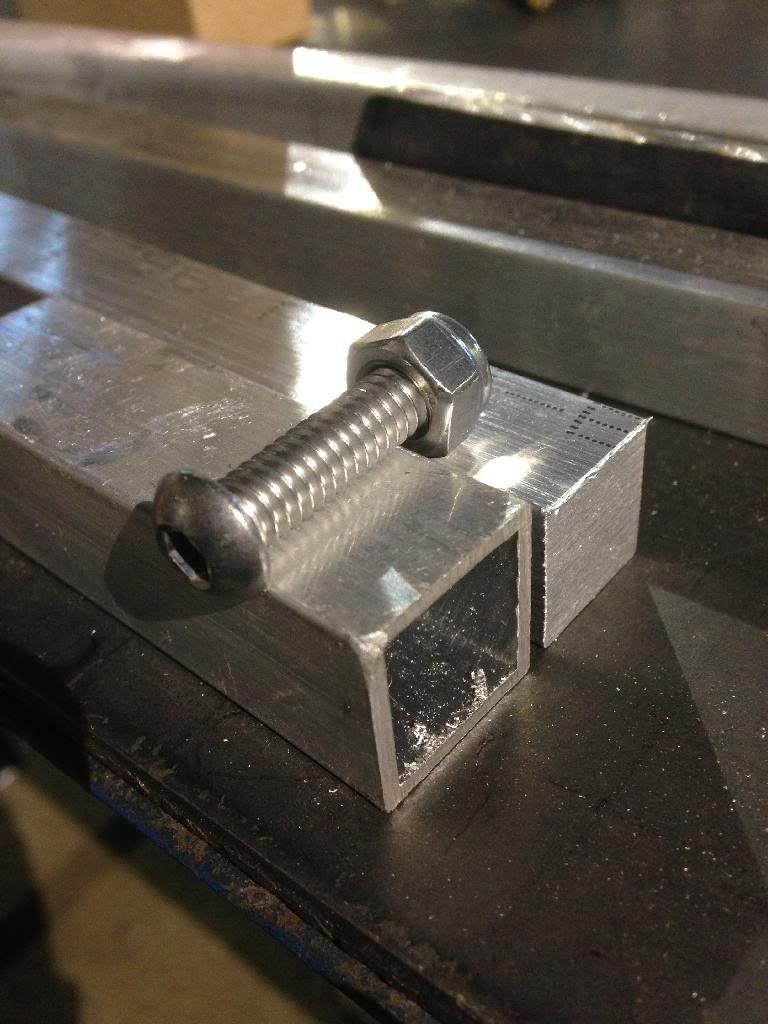

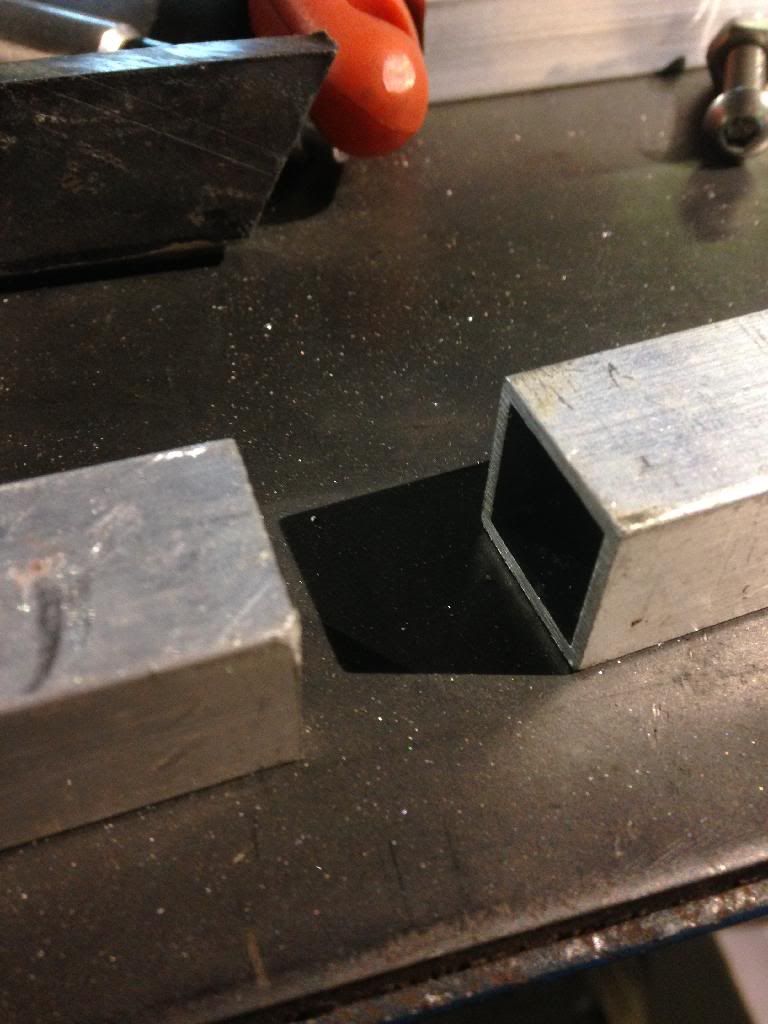

I'm building some enclosures that need to break down for easy transportation and can't find an easy way to make a "quick connect" or bolt connection where these tube ends meet. The material is 3/4 aluminum square tube 1/16 wall. I was hoping I could use 5/8 square stock to slip inside and weld to one end, then secure the other end with a nut and bolt. 5/8 is too big of course and I can't find 9/16 al stock anywhere. Can anyone suggest a method to secure these? It preferably needs to be inside the tube and not a sleeve.