I think theres some around here, but there not mind readers. so start talkin

Morning all, not sure if this is the right location for this thread but I've got a few questions for weld inspectors. Thank you.

Sent from my iPhone using Tapatalk

I think theres some around here, but there not mind readers. so start talkin

Doesn't matter what he's going to ask. I can already tell it's going to be his fault.

Dave J.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

Dave J.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

Dave J.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

Porosity??? Hell man, those are pre-placed stop crack holes I put there on purpose.

Definitely not my fault lol

My questions pertain to the CWI exam and about NDT. I'd like to finally take the exam this summer but I'm wondering if I shouldn't get more NDT done before hand? If I land s job as an inspector and the job requires RT and I'm not qualified then all I'd do is paperwork correct?

Sent from my iPhone using Tapatalk

There's still all the visual inspection that needs to be done. And if you already have your CWI more companies would probably be willing to give you the training to get your level I, II or III's in the various NDT processes like RT, UT, MT, PT. The guys qualified to do those are also doing their fair share of paperwork. Being a CWI usually involves doing a lot of documentation no matter which of the additional (beyond VT) NDT processes you're using.

My advice is, if you think you're ready to take the CWI exam go ahead and take it. Having that should make it easier for you to get the more advanced RT training.

Another trend I've been seeing the last few years is that phased array UT is starting to get used a lot in place of RT. So if you were going to spend your own money to get some advanced NDT training I'd think UT would make you more valuable in the job market.

Rooster,

That sounds like a dam good plan to me. What you learn in them should definitely help you pass the CWI exam.

And since you mentioned wanting to start out in structural.....I've hardly seen any RT get used in structural inspection. UT is the major inspection method for the more critical structural stuff. Also lots of MT. The RT training will help you out more when you get into code pipe work.

Which code did you pick for the open book part of the test. I highly recommend you go with the D1.1. Especially if you want to work structural. Using the API 1104 for your CWI exam isn't always thought of that well. It's kind of considered to be the easy way when it comes to CWI bragging rights. My experience is that any one who can deal with the D1.1 never has much problem switching over to work to API 1104. On the other hand if all you're familiar with is the 1104 it can be kind of a steep learning curve to get a handle on the D1.1.

I'll de doing D1.1 for the exam mainly because it seems more "flexible" with getting jobs. I can always do a 1104 endorsement later.

I'm doing the RT class because that's the only one available in my area, without heading out of state for school it's the best option right now. The school offers more NDT but only one class a semester.

Sent from my iPhone using Tapatalk

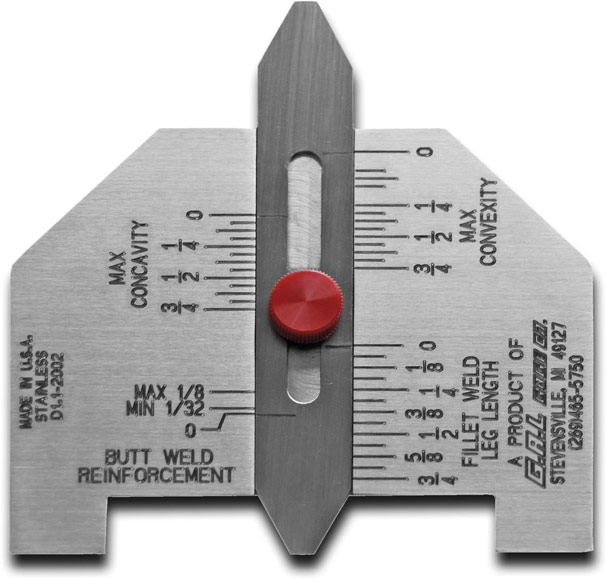

Here is simple tool

For checking welds

It check for both too little and to most weld

Dave

Found on the internet

Still made after 50 years

https://www.galgage.com/measuring_gauges.html

Last edited by smithdoor; 04-28-2018 at 09:18 PM.

HF 170 welder

HF 4x6 band saw

South Bend 9N

Mill

B&D mag drill

Victor torch

Doe to the tidal forces of lake Erie and the 9 months of winter ( like hay fever season but colder) welding is no longer permitted in Ohio-stan.

Rooster,

Never heard of getting any "endorsements" to your CWI for working to different codes. Maybe that's a new thing? I tested to the D1.1 and have inspected work to other codes over the years with out any. It's just a matter of getting the other codes and becoming familiar with them. I've always done that by "self study" and not any kind of official class. The open book part of the CWI exam is more for the purpose of proving that you know how to read, comprehend and use a code book than it is about the actual contents of any one particular code book.

Do you have a hard copy of the current D1.1 yet? Because if you don't I highly recommend you get one ASAP and start personalizing it. Get paperclips in strategic locations and use a highlighter to mark it up. The test is a timed event so you have to be able to find things as quickly as possible. The "index" at the end of the book will also be your friend. And just because you think you've found the right paragraph that answers the immediate question if there's any notes referencing any other paragraphs in other sections you need to be sure and go read them to make sure there's not some special circumstances that would pertain.

Just curious but do you already have some experience in the welding industry or are you just getting started out?

Rooster,

With that kind of welding background and amount of experience you shouldn't have any problem becoming a CWI. In fact I think those that come from a welding back ground end up making better inspectors than those that don't.

Are you an active member of your local AWS chapter? Because that's another good resource for becoming a CWI. At the time I took my test the local chapter where I was living put on a week end training seminar geared to helping people pass that test just a week or two before the test was given.

When it comes to codes for pipe welding two of the big ones are ASME B31.1 (power piping) and ASME B31.3 (process piping). Having a good working knowledge of ASME Section IX will help you also.

As far as NDI goes for taking the CWI test, the questions will only be related to whether you know about the process. It is not necessary to be certified in NDI. Secondly the welding standard you choose to use in the test is your choice. If you pass the test you are a CWI certified to inspect welds related to any code. It has nothing to do with the standard you used in the test.

Chris

Auction Addict

milo,

That's a pretty good way of putting that. To past the CWI test you have a good handle on the theory (and procedures used) for all those NDT (NDI) processes. To actually get "certified" Level I, II or III in any of them requires some form of proof of training (from an approved source) and some actual hours on the job doing it under the supervision of some one that already is certified. Basically you have to demonstrate / prove to some one else that you know how to do it correctly. Or at least that's how it should work. And when ever that happens you need to be sure and get copies of the paperwork involved for your own personal records so that further down the line some where you can provide documentation to possible new employers about the extent of your qualifications.