Hello,

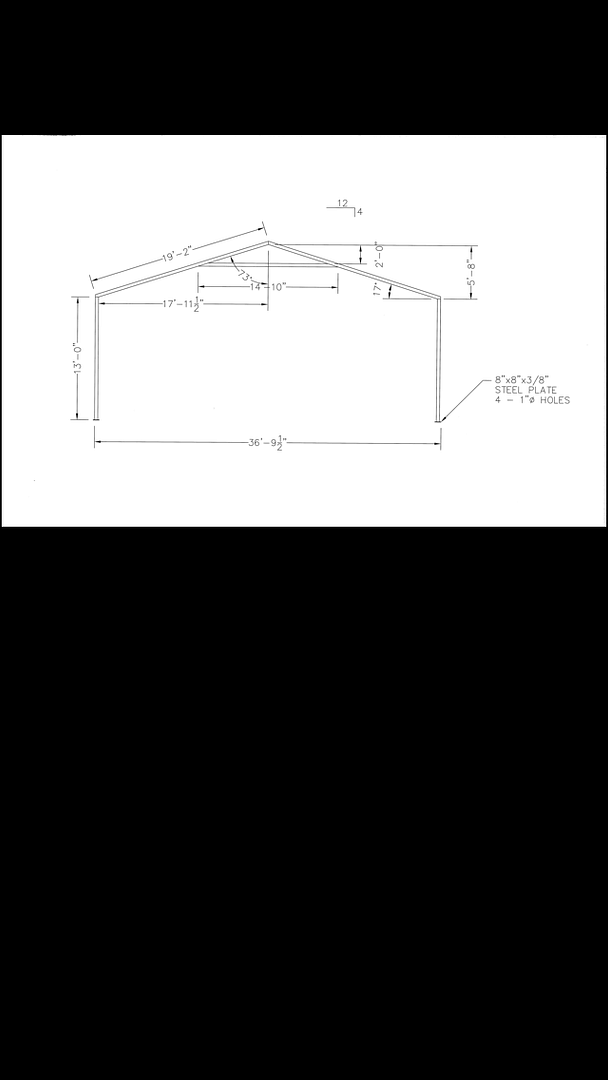

I was wondering if anyone knew where to find some plans to build a metal building out of square tubing. Looking for a 20'x30' or something in that area? I would like to be able to buy the raw materals and make it. Not a kit that bolts together. I'd love to be able to weld up the sides and such in panles and then set them in place when done.

I cant find any websites with plans for sale to do this. Everything is pre fabraicated so it seems...

I saw and kinda like the post a while back about the two car garage that the guy welded up, but it wasn't engineered at all. I want and need something like that, but designed and engineered..

Any one know of any??

thanks,

I was wondering if anyone knew where to find some plans to build a metal building out of square tubing. Looking for a 20'x30' or something in that area? I would like to be able to buy the raw materals and make it. Not a kit that bolts together. I'd love to be able to weld up the sides and such in panles and then set them in place when done.

I cant find any websites with plans for sale to do this. Everything is pre fabraicated so it seems...

I saw and kinda like the post a while back about the two car garage that the guy welded up, but it wasn't engineered at all. I want and need something like that, but designed and engineered..

Any one know of any??

thanks,